The installation of the planetary gearbox is a relatively simple process, but some details need to be paid attention to during the installation process. The installation process of the planetary gearbox is roughly divided into three steps:

1. check the size matching,

2. installation, and

3. testing.

The main thing is to confirm the planetary gear. The coaxiality of the gearbox during installation will have a great impact, so let's learn about the installation process of the planetary gearbox and some precautions!

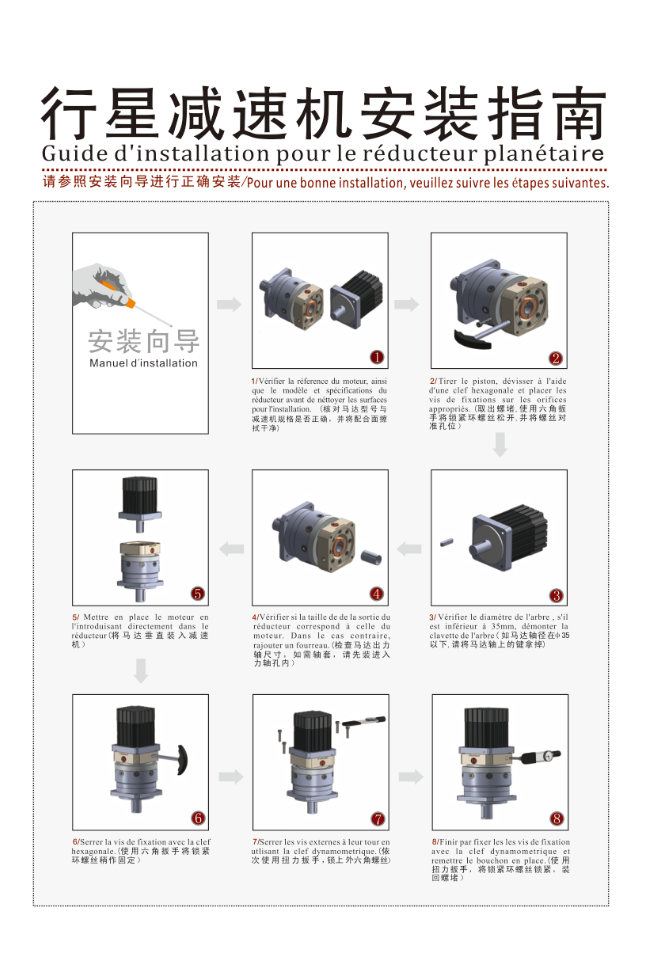

Before installing the planetary gearbox and the motor, it is necessary to confirm whether they are in good condition, and it is necessary to check whether the dimensions of the connected parts match, mainly referring to whether the installation size between the motor and the gearbox is correct.

Send the screws of the dust-proof holes on the outer side of the planetary gearbox, adjust the position to align the side holes and the dust-proof holes, remove the motor shaft key, and carry out anti-rust treatment on the installation parts of the motor and the gearbox to ensure the tightness of the connection and the later operation of fluency.

When connecting, it is necessary to ensure that the coaxiality between the two is consistent.

If it is inconsistent, it will affect the later operation, wear the internal gear of the gearbox or break the shaft. During the installation process, it is forbidden to hit the gearbox with a hammer to prevent damage caused by excessive axial force or radial force.

When the gearbox and the motor are connected, first install the diagonal screws to ensure uniform force, then install the other two diagonal bolts, tighten the four mounting bolts one by one, and finally tighten the captive screws on both sides, some high-precision installation requires the use of a torque wrench.

After the gearbox is installed, it needs to be fixed on the bracket, and the stability of the installation needs to be ensured.

If the gearbox is unstable during high-speed operation, it may cause vibration and external noise, which will indirectly affect the coaxiality of the installation.

When gears or other components are externally installed during transmission, protective devices need to be installed.

After the installation is completed, check the stability and flexibility of the installation parts in turn, and the idling test can be carried out. The operation process should be relatively stable, without obvious vibration and noise. When there are some abnormal phenomena, the problem should be eliminated.

The planetary gearbox needs to be carefully installed during the installation process. Good installation can achieve twice the result with half the effort. Installation according to standard procedures can save a lot of maintenance costs in the later period. If the coaxiality is inconsistent during installation, it will have a great impact on the later use and the gearbox itself. Therefore, during the installation of the gearbox, attention must be paid to the coaxiality of the gearbox and some details.

An installation notice will be provided with each gearbox Motoreducer sells. You can refer to it and make sure it is done according to the right process!